In 1815, Sir Humphrey Davy patented an oil lamp for use in coal mines, and coincidentally pioneered the movement to provide safe and reliable products for use in explosion-prone environments. In the days before electricity, miners used lamps that burned fuel oil for lighting. The problem with that was, deposits of underground coal are almost always accompanied by methane gas pockets which, when mixed with coal dust in proximity to an open flame, created terrible and deadly explosions. Davy’s design incorporated a brass net around the wick chamber that let the light out, and let oxygen (necessary for combustion of the fuel oil) in, but if methane entered the wick chamber, it’d extinguish the flame and prevent ignition of the gas outside the lamp.

Industrial growth and the proliferation of electricity that (literally) powered it introduced new hazards in a number of industries other than just mining…which grew exponentially through the 19th century, since coal was the main fuel in electric generating plants. As hazards were identified (usually, unfortunately, by a tragic accident), new and safer products were developed, and eventually, industry professionals implemented controls & standards to make sure these new and safer products were designed, manufactured, and used for the prevention of future tragic accidents.

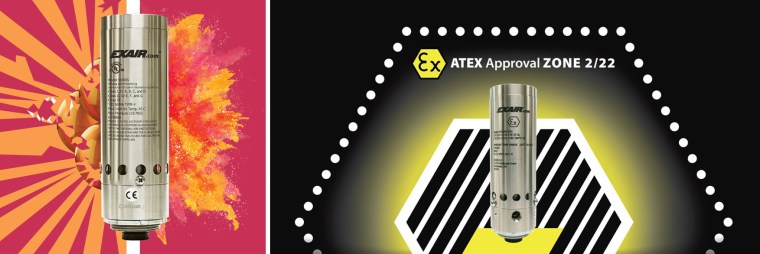

In North America, the National Electrical Code’s (NEC) system of Classes and Divisions specifies requirements of electrical product testing & use to ensure safety in this regard. In 2014, the European Union created the ATEX Directive, which specifies similar (but not identical) requirements, also aimed at mitigating explosion risks in industrial environments. In 2019, EXAIR introduced our HazLoc Cabinet Cooler Systems, which comply with certain NEC requirements, and we just recently introduced ATEX Cabinet Cooler Systems to comply with that directive.

Like our HazLoc Cabinet Cooler Systems, their ATEX counterparts have been subject to stringent UL testing to ensure compliance with the ATEX Directive. They’re approved for use in areas defined by the Directive as:

- Zone 2 (an atmosphere where a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation, but if it does occur, will persist for a short period only) and

- Zone 22 (an atmosphere where a mixture of air and flammable substances in the form of powder or dust is not likely to occur in normal operation, but if it does occur, will persist for a short period only.)

This fall, EXAIR will celebrate 40 years of dedication to safety and efficiency in engineering & manufacturing compressed air products for a wide range of applications. If you’d like to find out how our Cabinet Cooler Systems – or any of our Intelligent Compressed Air Products – can increase safety and efficiency, and lower sound levels for your compressed air usage, give me a call.

Russ Bowman, CCASS

Application Engineer

Visit us on the Web

Follow me on Twitter

Like us on Facebook