Progressive cavity pumps are essential in numerous industries, known for their ability to handle a wide range of fluids with varying viscosities. To ensure these pumps operate efficiently, it is crucial to understand the importance of OEM spare parts. This guide will delve into the significance of progressive cavity OEM spare parts, their benefits, and how to choose the right components for your needs.

What Are Progressive Cavity Pumps?

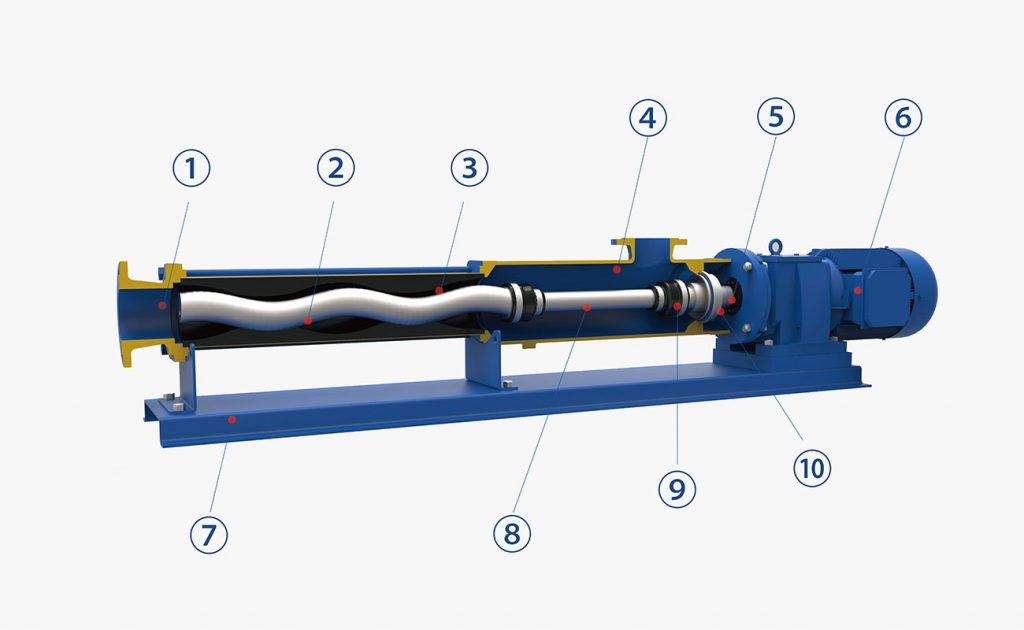

Progressive cavity pumps consist of a helical rotor and a stator, creating a series of cavities that transport fluids. They are widely used in applications such as wastewater treatment, food processing, and oil extraction. The reliability of these pumps heavily depends on the quality of their components, particularly OEM spare parts.

Importance of OEM Spare Parts

When it comes to maintaining progressive cavity pumps, using OEM spare parts is paramount. Here are several reasons why:

Quality Assurance

OEM spare parts are produced by the original manufacturer, ensuring that they meet the specific standards and requirements of the pump. This guarantees that the parts will fit correctly and function optimally, reducing the risk of malfunctions.

Longevity and Reliability

Using OEM parts can significantly extend the lifespan of your progressive cavity pump. These parts are designed to withstand the demanding conditions in which the pumps operate, ensuring they perform reliably over time.

Compatibility

OEM spare parts are specifically designed for your pump model, ensuring compatibility. This minimizes the risks associated with using generic or aftermarket components, which may not fit correctly or function as intended.

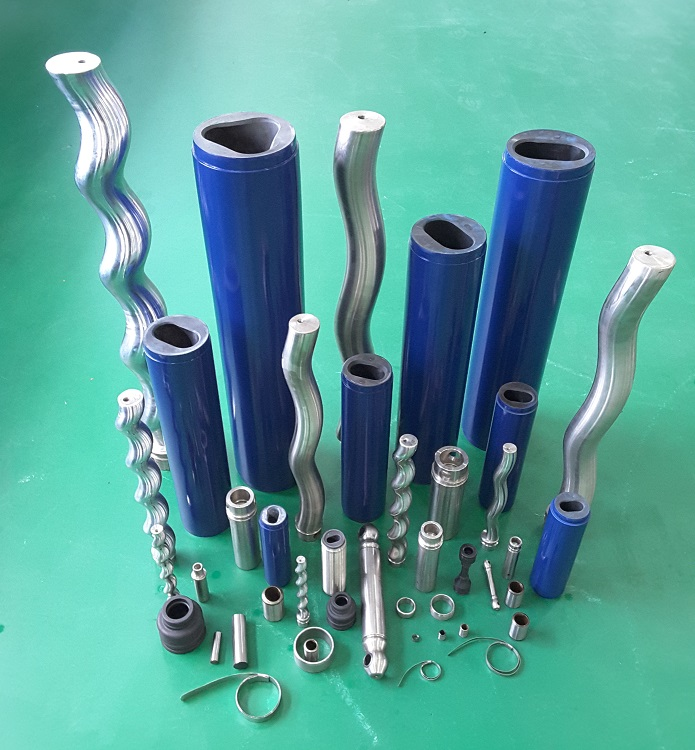

Common Progressive Cavity OEM Spare Parts

To maintain the efficiency and reliability of progressive cavity pumps, it’s essential to be familiar with the common OEM spare parts. Here’s a list of crucial components:

- Rotor: The rotor is the primary moving part that creates the pumping action. Ensuring its quality is vital for optimal performance.

- Stator: The stator works in conjunction with the rotor. A worn or damaged stator can lead to decreased efficiency and increased maintenance costs.

- Suction and Discharge Hoses: These hoses are essential for fluid transport. High-quality hoses prevent leaks and ensure smooth operation.

- Seals and Gaskets: These components prevent fluid leaks and protect internal parts from contamination.

- Bearings: Bearings support the rotor and allow for smooth operation. Worn bearings can lead to increased friction and pump failure.

- Drive Shaft: The drive shaft transmits power from the motor to the rotor. A robust drive shaft is essential for the pump’s overall efficiency.

Benefits of Using OEM Spare Parts

Opting for OEM spare parts over generic alternatives can offer several advantages:

Enhanced Performance

OEM parts are engineered to work seamlessly with your pump, ensuring optimal performance. This can lead to increased efficiency and reduced operational costs.

Reduced Downtime

By using high-quality OEM parts, you minimize the risk of breakdowns and malfunctions. This translates to less downtime and higher productivity for your operations.

Better Support and Warranty

OEM manufacturers often provide better support and warranties for their spare parts. This means that if issues arise, you have direct access to expert assistance.

Choosing the Right OEM Spare Parts

Selecting the appropriate OEM spare parts for your progressive cavity pump involves several considerations:

Identify Your Pump Model

Before purchasing any spare parts, ensure you know your pump model and specifications. This information is crucial for compatibility.

Consult the Manufacturer

If you’re unsure about the right parts, consult the manufacturer’s guidelines or reach out to their support team. They can provide valuable insights and recommendations.

Consider Your Application

Different applications may require specific components or materials. Always consider the fluid type, temperature, and operating conditions when selecting parts.

Evaluate Supplier Reputation

When sourcing OEM spare parts, choose reputable suppliers. Look for those with a proven track record of quality and reliability.

Conclusion

In conclusion, understanding the role of progressive cavity OEM spare parts is essential for maintaining the efficiency and longevity of your pumps. By prioritizing quality, compatibility, and reliability, you can ensure that your progressive cavity pumps operate at their best. Remember to consult manufacturers and consider your specific application needs when selecting spare parts. With the right components, you can enhance your pump’s performance and minimize downtime, ultimately leading to greater operational success.