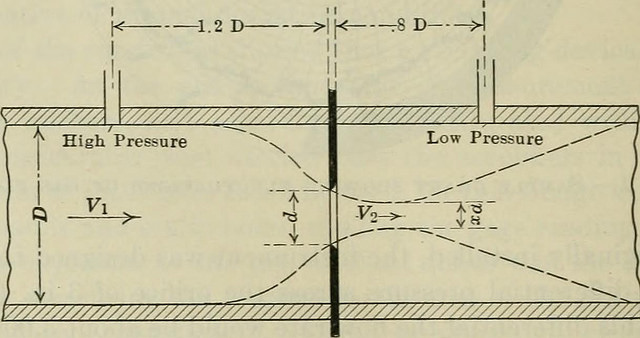

EXAIR Intelligent Compressed Air Products incorporate several distinct principles of fluidics into our engineered designs. To be clear, these principles aren’t exclusive to making quiet and efficient compressed air products. I personally have used them all for business and pleasure over the years. In the Navy, for example, the air ejectors that pulled vacuum on the main condensers where our turbines dumped their ‘used’ steam were basically great big Venturis – they restricted the diameter through which a fluid (steam, in this case) flowed, gradually increased that diameter, and doing so, changed the velocity so that a low pressure area (or vacuum) developed in the throat:

EXAIR E-Vac Vacuum Generators use the Venturi effect to draw vacuum of up to 27″Hg. They’re typically used with Vacuum Cups for pick-and-place material handling applications.

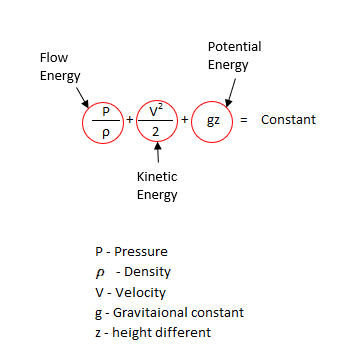

I first learned about the Bernoulli principle on a grade school field trip to the National Air Force Museum at Wright Patterson Air Force Base, about an hour from where I grew up. See, this Bernoulli guy discovered that when there is an increase in the speed of a fluid, a simultaneous decrease in fluid pressure occurs at the same time. That’s why airplane wings are shaped like they are – flat on the bottom and curved on top…when the air flowing that extra distance over the top speeds up to get to the back of the wing as fast as the air that’s simply flowing underneath the wing does, the decrease in pressure on top causes the wing (and the plane it’s attached to) rise in the air.

The Bernoulli principle is incorporated in to the design & operation of EXAIR engineered Air Knives, Air Wipes, Air Amplifiers, and Air Nozzles.

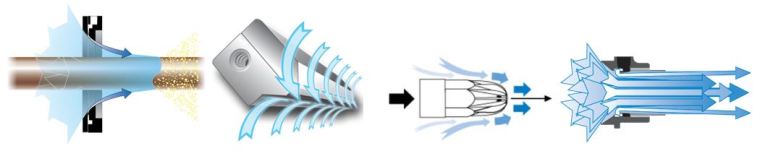

The Coanda effect is the third fluidics principle that’s incorporated into the design & operation of many EXAIR engineered compressed air products. Its namesake, Henri Coanda, was an early 20th Century aeronautical engineer who discovered that if a jet of fluid exiting an orifice flows across a surface, it’ll tend to not only adhere to and follow that surface (even if it curves or bends), but also entrain fluid from the surrounding area.

There are a couple of easy – and interesting – experiments that demonstrate the Coanda effect, both of which I used when I was a Cub Scout leader and our Pack’s Webelos den was earning their Science Activity Pin:

Turn a faucet on and let the running water flow over the convex ‘bottom’ of a spoon. Everything we know about the laws of gravity say that when the water reaches the ‘bottom-most’ point on the spoon’s convex surface, it ought to fall straight down…but it doesn’t:

Another experiment that defies everything we think we know about gravity can be performed with a ball, and a source of air flow. Here’s a short video, showing how the air flow from an Air Amplifier ‘wraps’ around a ball and holds it in that jet of air:

For forty years now, EXAIR has been putting these principles of fluidics into practice by engineering & manufacturing the most efficient, quietest, and safest compressed air products on the market. If you’d like to find out how we can help you get the most out of our products – and your compressed air system – give me a call.

Russ Bowman, CCASS

Application Engineer

Visit us on the Web

Follow me on Twitter

Like us on Facebook