Return on Investment, or ROI, is the ratio of profit over total investment. Many people use it to check investment stocks, financial markets, capital equipment, etc. It is a quantitative way in determining the validity for an investment or project. You can use this ROI value to give a measurable rate in looking at your investment, no matter how big or small. In this blog, I will compare the ROI between an EXAIR Super Air Knife to a home-made drilled pipe. Let’s start by looking at Equation 1 to calculate the Return on Investment. For a positive ROI value, the project will pay for itself in less than one year. Any negative values would represent a high-risk investment.

Equation 1: ROI = (Total Annual Savings – Total Project Cost) / Total Project Cost * 100

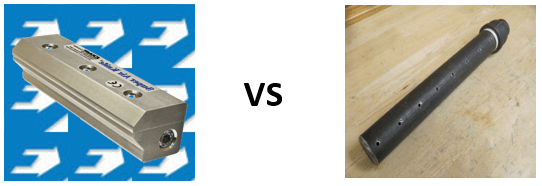

The Total Project Cost is the cost of the product with the labor to install. In our example, we will use a 36” (914mm) blow-off device to cover the width of a conveyor. One device will be an inexpensive drilled pipe and the other will be a high-efficiency EXAIR Super Air Knife. The drilled pipe had (72) 1/16” (1.6mm) diameter holes spaced ½” (13mm) apart. EXAIR manufactures the model 110036 36” Aluminum Super Air Knife with a .002” (.05mm) shim along the entire length. The model 110036 has a retail price of $802.00 each. The cost of the home-made drilled pipe was around $70.00 for material and labor. What a difference in price! It seems like the ROI should be in the negative, but is it?

Let’s continue on with the Return on Investment. The amount of time required to install the Super Air Knife across the conveyor only took a maintenance staff about one hour to mount. The labor rate that I will use in this example is $80.00 per hour (you can change this to your current labor rate). The labor cost to install the knife is $80.00. The Total Project Cost can be calculated as follows: $802 + $80.00 = $882.00. The next part of the equation, Total Annual Savings, is a bit more in-depth, but the calculation is below.

To calculate the Total Annual Savings, the amount of compressed air used by the drilled pipe is around 261 SCFM (7,389 SLPM) at 60 PSIG (4.1 Bar). The model 110036 Super Air Knife has an air consumption of 82.8 SCFM (2,344 SLPM) at 60 PSIG (4.1 Bar). With an electrical rate of $0.08 per Kilowatt-hour, the electrical cost is near $0.25 per 1000 standard cubic feet or compressed air, or $0.25/1000SCF. To calculate an annual savings, let’s use a blow-off operation of 8 hours/day for 250 days a year. Replacing the drilled pipe with the model 110036 Super Air Knife, it will save you (261 SCFM – 82.8 SCFM) = 178.2 SCFM of compressed air. To put this into a monetary value, the annual savings will be 178.2 SCFM *$0.25/1000SCF * 60 Min/hr * 8hr/day * 250 day/yr = $5,346.00 per year.

With the Total Annual Cost and the Project Cost known, we can insert these values into Equation 1 to calculate the ROI:

ROI = (Total annual savings – Total Project Cost) / Project Cost * 100

ROI = ($5,346.00 – $882.00) / $882.00 * 100

ROI = 506%

With a percentage value that high, we are looking at a payback period of only 40 days. You may look at the initial cost and be discouraged; but in a little over a month, the model 110036 will have paid for itself. And after using it for one year, it will save your company $5,346.00.

In my experience, a loud blowing noise from your equipment is generally coming from an inefficient and safety-concerned product. With these “cheap” ways to blow compressed air, it will cost your company a lot of money to use as shown in the example above. EXAIR has an Air Savings Calculator on our website to calculate the savings by replacing your inefficient blow-off devices. And, if you would like to team up with EXAIR to find ways to increase savings, improve productivity, and promote safety, you can contact an Application Engineer. We can help you get started by defining your Return on Investment with EXAIR products.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb