Fluid mechanics is the field that studies the properties of fluids in various states. There are two main areas; fluid statics and fluid dynamics. Fluid dynamics studies the forces on a fluid, either as a liquid or a gas, during motion. Osborne Reynolds, an Irish innovator, popularized this dynamic with a dimensionless number, Re. This number determines the state in which the fluid is moving; either laminar flow, transitional flow, or turbulent flow. Equation 1 below shows the relationship between the inertial forces of the fluid as compared to the viscous forces.

Equation 1: Re = V * Dh/u

Re – Reynolds Number (no dimensions)

V – Velocity (feet/sec or meters/sec)

Dh – hydraulic diameter (feet or meters)

u – Kinematic Viscosity (feet^2/sec or meter^2/sec)

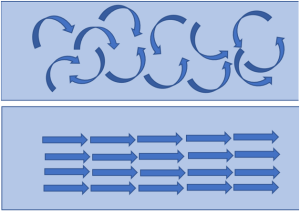

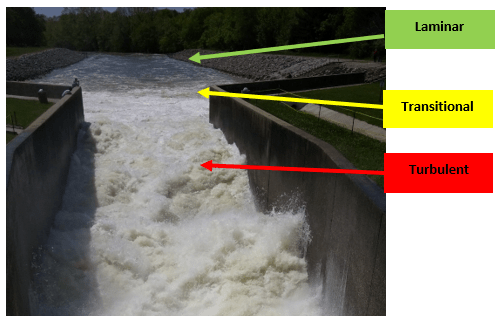

The value of Re will mark the region in which the fluid (liquid or gas) is moving. If the Reynolds number, Re, is below 2300, then it is considered to be laminar (streamline and predictable). If Re is greater than 4000, then it is considered to be turbulent (chaotic and violent). The area between these two numbers is the transitional area where you can have eddy currents and some non-linear velocities. To better show the differences between each state, I have a picture below that shows water flowing from a drain pipe into a channel. The water is loud and disorderly; traveling in different directions, even upstream. With the high velocity of water coming out of the drain pipe, the inertial forces are greater than the viscous forces of the water. This indicates turbulent flow with a Reynolds number larger than 4000. As the water flows into the mouth of the river, the waves transform from a disorderly mess into a more uniform stream. This is the transitional region. A bit further downstream, the stream becomes calm and quiet, flowing in the same direction. This is laminar flow. Air is also a fluid, and it will behave in a similar way depending on the Reynolds number.

Why is this important to know? In certain applications, one state may be better suited than the other. For mixing, suspension and heat transfer; turbulent flows are better. But, when it comes to effective blowing, lower pressure drops and reduced noise levels; laminar flows are better. In many compressed air applications, the laminar region is the best method to generate a strong force efficiently and quietly. EXAIR offers a large line of products, including the Super Air Knives, Super Air Amplifiers and Super Air Nozzles that utilizes that laminar flow for compressed air applications. If you would like to discuss further how laminar flows could benefit your process, an EXAIR Application Engineer will be happy to help you.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb