When it comes to die stamping, friction generates heat. Heat can be a problematic cause for generating scrap, slowing production speeds, and decreasing tool life. A manufacturer of film reels was seeing the effects during their process. They had a stamping machine that was creating the sprocket holes in the outer edge of a 35mm film. These holes are used for advancing the reel strip through printers, projectors, and processing machines. They had to be particularly careful, as film materials warp easily with heat. Some of us remember the film reels that would bubble and burn out when the film stopped in the projector too long. So, speed was critical without creating any quality issues.

The film reel manufacturer was intrigued with the EXAIR Vortex Tubes as they can generate cold air by only using compressed air. They do not use refrigerants or have any moving parts. They are very compact and can fit into tight places. The manufacturer thought that if they could reduce the temperature in the stamping process, they could speed up production.

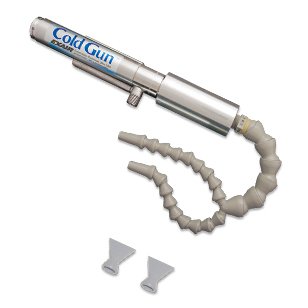

EXAIR makes different accessories available to help with installation and function of Vortex Tubes for various applications. For this customer, I recommended the model 5315 Cold Gun System. This product generates 1000 BTU/hr of cooling power, and has a Dual Point Hose Kit to allow for targeting both sides of the film reel. It includes an incorporated, magnetic base to securely position it on a ferromagnetic surface of the stamping machine. Finally, it includes two 1” flat nozzles to spread the cooling airflow out a bit. These flat nozzles would help to direct the cold air in between the two stamping plates. They were able to keep the film reel and the die stamp cool as they sped up their operation. Even with the additional speed, they also noticed that the die stayed sharper 20% longer which allowed for a corresponding productivity increase .

If heat is slowing down your process, EXAIR will most likely have a product to keep it cool. As with the customer above, heat was a “reel” problem. With the Cold Gun System, we were able to increase their productivity and decrease their downtime. Please contact an Application Engineer to discuss your application if temperature is affecting your process.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb

Photo by: Film by JanBaby Creative Commons CC0 Public Domain