When it comes to liquid spraying, EXAIR is introducing a new size to the line of all liquid nozzles. They are engineered to spin the liquid in order to break the surface tension. Passing through a precision orifice, the liquid will break into fine particles. The smaller the particle size, the greater the surface area, which reduces liquid use. Now we are adding the brand new 1/8″ NPT HollowStream Nozzle to our product offering!

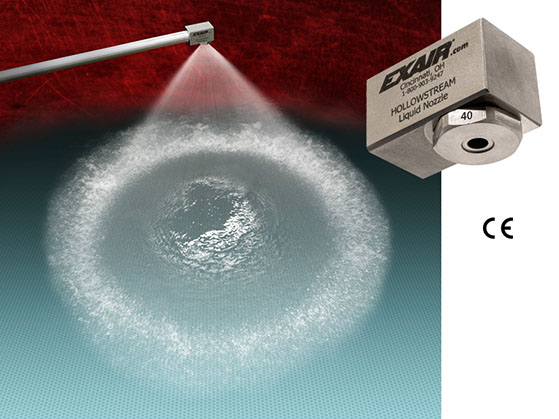

The HollowStream™ Cone Liquid Nozzles produce a liquid ring on the target. This will reduce liquid use when compared to our FullStream™ Cone Liquid Nozzles. They are available in NPT and BSP female threads in the new 1/8, ¼, 3/8, and 1/2 sizes with varying liquid flow rates. They are all made of 303 stainless steel with a vane-less design to help resist clogging. They can handle 250 PSIG (17.2 barg) of liquid pressure and operate at temperatures up to 800oF (427oC). Some applications would include cooling, quenching, washing, foam breaking, sanitizing, and de-greasing.

With six different styles that range from 0.1 to 1.0 GPM, it adds even more flexibility to our Liquid-only spray nozzles! You can see the new body dimensions below and the flow rates at 3-60 PSI of liquid pressure under the Specifications here! https://www.exair.com/phl80x5ss.html

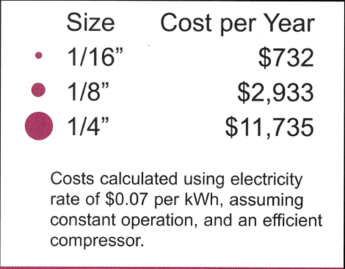

If you have a process where you need to reduce the amount of liquid to save money, EXAIR offers a line of Liquid Atomizing Nozzles as well as Air Atomizing Nozzles. The design is to reduce the droplet size to increase coverage. Here is a blog with the Air Atomizing Nozzles for improving Gummy Candy Production. In either case, if you have questions regarding how we can reduce costs and improve processes, you can contact an Application Engineer. We will be happy to help you.

Jordan Shouse

Application Engineer

Email: Jordanshouse@exair.com

Twitter: @EXAIR_JS